Aggregates: The Science Behind the Stone

Aggregates are often overlooked in the construction industry. However, they are a vital part of many building products. They can be made from recycled materials and provide many different uses. If you work on a construction site, it is likely you have handled aggregates before, but how much do you know about stone products?

Here is the science behind aggregates.

What Are Aggregates?

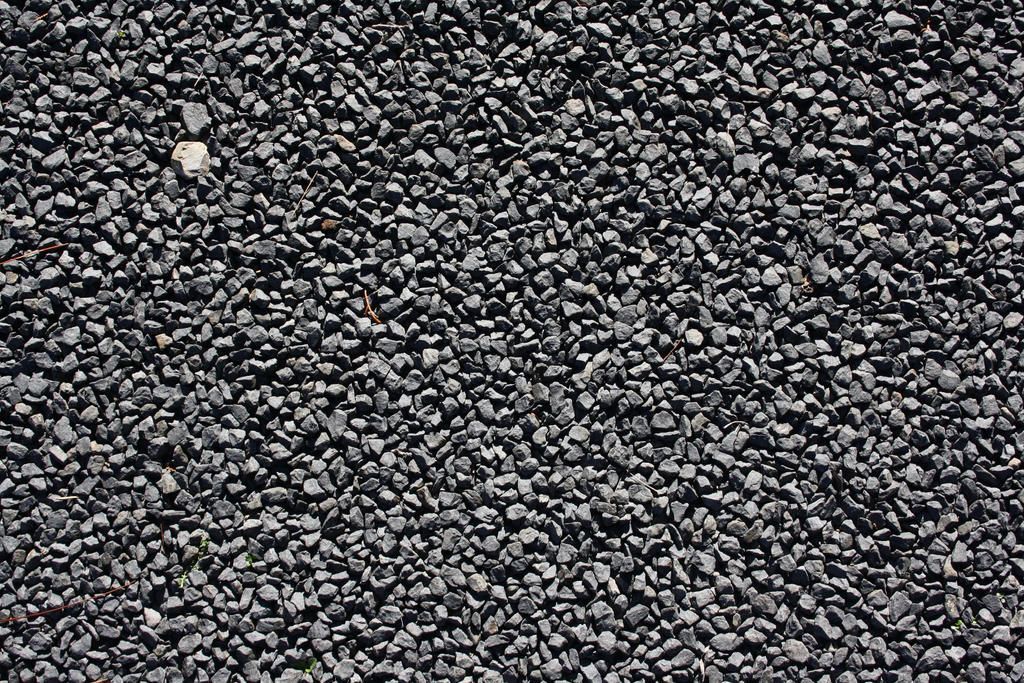

Aggregates are a type of raw material created using natural sources which are extracted from quarries and pits and include gravel, crushed stone, gabion stone and sand. They can be used with a binding material such as water, cement and asphalt to create compound materials such as asphalt concrete. Sand, gravel and crushed stone are all considered to be aggregates. Put simply, aggregates include grains or fragments of rock. However, they aren’t renewable but are used widely in everything we see so it’s great to learn more about them.

What Are Aggregates Used For?

Aggregates are used in many ways for construction including foundations, concrete blocks, brick, mortar, shingles, steel, glass and asphalt, among many others. Aggregates are used in many structures we see everyday such as,

- Urban and rural infrastructures including residential and commercial buildings

- Motorways, bridges, pavements and car parks

- Factories, power generation facilities

- Water storage, filtration and delivery systems

- Wastewater collection and treatment systems

Aggregate Production

Aggregates such as sand and gravel are a product of bedrock erosion and the transport, abrasion and deposition of these materials. Sand and gravel are mined from open pits or quarries or dredged from underwater depots. They can be mined with conventional earth-moving equipment such as bulldozers, front loaders and scraper graders.

Crushed stone aggregates are produced from bedrock, but not all bedrock can be used for aggregates. Different rocks have different qualities, for example, some rocks may be too soft while others are too chemically reactive. If there is bedrock that is suitable for mining, it must be drilled and blasted to break apart. Holes are drilled into the rock and then filled with explosives, while holes on top of the rock are filled with non-explosive materials to act as a plug. The explosion produces small fragments of rock which may need to be broken up more if they are too big. This is achieved using hydraulic hammers, drop balls and other devices.

Are you looking for

quality aggregates and stone products such as gabion stone and crushed stone?

Get in touch with WM Thompson & Sons today.