From Quarry to Construction Site: The Journey of Natural Stone and Aggregate

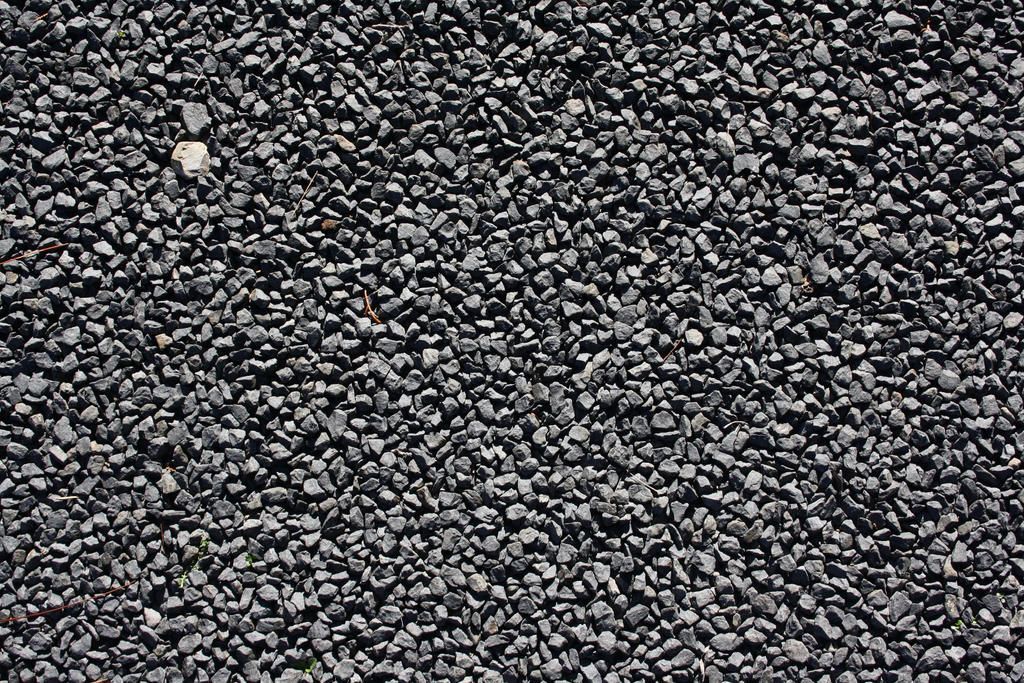

When you pass a new building, a freshly laid road, or a landscaped garden, it’s easy to overlook one of the most vital ingredients in every project, aggregate. From gravel and sand to crushed stone and concrete, these materials form the solid foundation of the built environment. But how do they make their way from the ground beneath our feet to the structures we rely on every day? Let’s explore the journey of natural stone and aggregate, from quarry to construction site.

The Beginning: Quarrying the Raw Material

The process starts deep within the quarry, where raw materials such as limestone, sandstone, and granite are carefully extracted. At Thompson Quarries, safety and sustainability are at the heart of every operation. Skilled teams use modern equipment to break down rock formations efficiently while minimising environmental impact. Each quarry site is chosen for the quality and consistency of its stone, ensuring that only the best materials are supplied to clients across Scotland.

Once the rock is extracted, it’s transported to a crushing and screening facility, where it’s processed into various sizes and grades. This ensures that every batch meets the precise requirements for its intended use, whether for road construction, drainage, concrete production, or decorative landscaping.

Quality Control and Processing

After extraction, the material undergoes rigorous testing and quality control. Aggregates must meet strict industry standards for strength, size, and cleanliness. At Thompson Quarries, samples are regularly analysed to ensure compliance with BS EN specifications and environmental best practices.

The stone is then crushed and screened to create different products, from coarse sub-base materials to fine sand and decorative chips. Advanced machinery and skilled operators ensure consistency, while water suppression systems reduce dust and maintain cleaner, safer working conditions.

Transport and Logistics

Once processed, the aggregates are stockpiled, ready for delivery. Getting materials from the quarry to the customer efficiently and responsibly is a key part of the journey. Thompson Quarries operates a modern fleet of haulage vehicles, ensuring timely deliveries to construction sites across Scotland. Routes are planned strategically to reduce carbon emissions and fuel consumption, aligning with the company’s commitment to sustainability.

The Final Destination: Construction and Beyond

At the construction site, aggregates are transformed into the materials that shape our world. They are mixed into concrete, spread under roads, or used as drainage layers beneath buildings. Every tonne of stone plays a crucial role in supporting safe, durable, and long-lasting infrastructure.

Once their purpose is fulfilled, aggregates can even begin a new life through recycling. Thompson Quarries also produces high-quality recycled aggregates, reducing waste and conserving natural resources, a key step toward a circular economy.

Building the Future from the Ground Up

The journey of natural stone and aggregate is one of transformation, from solid rock beneath the earth to the sturdy foundations of modern life. At

Thompson Quarries, that journey is driven by expertise, responsibility, and a dedication to quality. Whether it’s for a large civil engineering project or a small local build, every load of aggregate tells a story of craftsmanship, care, and commitment to Scotland’s construction future.